Product series description UNISTERI® HP IL

Modular Layout System

- single-door and double-door (interlaying) version with possibility of building into the stainless steel wall

- optional steam source – own, external, combined

- optional roughness of inner surface of the sterilization chamber

- system for manual insertion of materials and system of transport and charging carts

- wide range of optional program equipment

- various possibilities of batch documentation processing

- wide range of optional equipment for minimization of operation costs

- possibility of specific additives selection (e.g. possibility of chamber equipment with a flexible sensor PT 100 for safe and precise control of cycles while working with microbiological cultures and solutions, possibility of building-in the device for additional cooling of condensate, possibility of adjustment for decontamination of materials, gastight version “Bio-Seal”, pressure manometers, wide range of individual adjustments of programs, …)

- wide spectrum of services (incl. ON-LINE internet diagnostics, various types of tests, validation, etc.)

Unique Microprocessor Control

- the highest possible operation safety, double system of sensors for process information collection and assessment and for their continuous comparison and assessment

- two built-in microprocessor control systems (Master-Slave) for independent assessment, control and documentation of operation cycles

- any established variation exceeding allowed limits induces an error message

- unique error protocol for exact and fast diagnostics of errors

- the basic program equipment includes up to 50 standard programs

- easy realization of individual adjustments of programs

- easy import / export of programs using a USB flash disc

- easy and intuitive access for service allows a technician to comfortably set all and any calibrations and configurations and to perform fast diagnostics of the device

- the Audit Trail function allows you to record, view and archive important events

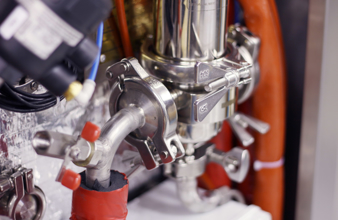

Pressure Sterilization Chamber

- the pressure chamber is heated by steam through heating jacket and it is made of high-quality stainless steel 1.4404 (AISI 316 L)

- special method of control of continuous steam filling into the steam sterilizer chamber

- down bottom of the sterilization chamber for perfect drying

- sterilization chamber with ground surface with roughness of Ra 1,25 μm (Ra 50 μinch); optional polishing with roughness Ra 0,8 μm (Ra 32 μinch) or polishing to mirror shine with surface roughness Ra 0,125 μm (Ra 5 μinch)

- thanks to high-quality insulation materials Rockwool used (no chlorides)

- equipped with an Al foil, there are reduced the radiated heat losses and requirements towards air-conditioning

- as a standard, all the sterilization chambers are equipped for validation with two easily accessible inlet necks

- new, unique, horizontally revolving, automatically lockable door fixed in four points

- if required, we perform chamber passivation (staining)

Steam Generator

- the steam generator together with the heating elements is made of high-quality stainless steel 1.4571 (AISI 316 Ti)

- high-quality Rockwool insulation with AL foil significantly reduces heat loss

- unique automatic control of the steam generator including water filling

- thermal degassing of feed demi water (optional) and automatic desalination to minimize non-condensable gases and for consistently high steam quality

Touch Control Panel

- user friendly, with intuitive control

- two built-in microprocessor control systems (Master-Slave) with own sensors for independent assessment, control and documentation of operation cycles

- ergonomic position of touch control panel

- touch screen technology 8,4“ provides well-organised and simple servicing on charging side

- on discharging side of the device (in case of two-door version): LED display with possibility of monitoring of current work phase, pressure in sterilization chamber and time left by the end of the cycle

- “Emergency stop” function integrated to the control panel allows for the device to be put into standby status if needed

- possibility of language selection for communication with the device

- well organised digital displaying of steam pressure in sterilization chamber shell and in steam generator, pressure and temperature in sterilization chamber (reference bottle)

- clock – an indicator of remaining time of the program and real time indicator

- error protocol with recording of all and any parameters at the moment of a fault for the possibility of fast or remote service

- visual and acoustic signalling of statuses and processes

- possibility of building-in a printer for sterilization processes documentation (optional equipment)

Wide Offer Of Working Programs

The UNISTERI® HP IL steam sterilizer can be used for sterilization of solid, porous and plastic materials, processing and subsequent sterilization of agars (substrates), sterilization of solutions in open and closed bottles, disinfection of materials, waste decontamination, etc.

The instrument enables the installation of up to the 50 fixed programmes in the basic version, according to the specific customer needs.

Sterilizing programmes with possibility of validation

- Universal 134°C/ 7 min, with following drying

- Universal Containers 134°C/ 7 min, with intensive drying

- Rubber 121°C/ 20 min, with following drying

- Instruments Quickly 134°C/ 4 min, with following short drying, for non packed instruments for immediately following use

Testing programmes

- Bowie&Dick Test – Steam penetration test – 134°C/ 3,5 min

- Vacuum Test – Chamber air tightness test – compensatory phase length is 5 min, test length is 10 min

The installed programs in the device can be modified at any time. The individual programs are downloaded to the device using a USB flash disc and can also be read back to the USB flash disc (up to 50 programs).

Special laboratory software

Enables to the operating personnel to make individual modifications of already programmed sterilization programmes.

The user can modify:

- sterilization temperature, the upper limit is 135 ° C

- sterilization time

- the drying phase duration

- number of drying phases

- number of evacuations

- for solution programs, the cooling temperature

- for programs controlled by the Fo parameter, the Fo parameter

We also offer special UNICONFIG software enabling to modify all values of the sterilisation cycle (evacuation, vacuum depth, exposition, drying) and to set the values of the sterilisation cycle temperature and time. (The verification by producer is necessary.)

Documentation of Batches

It is possible to arrange well-organized documentation of operation cycles by:

- independent documentation of operation cycles with recording with the possibility of saving recent protocols for the whole service life of the device

- connection to PC and by saving protocols in the computer memory using the “PrinterArchiv” software

- connection of the sterilizer to computer network (LAN) together with software application Ecosoft

- the electronic process documentation, data archiving and Audit Trail together meet FDA 21 CFR part 11 requirements

- by built-in printer

- possibility of batches export to PDF on the USB flash disc in the A4 format

Equipment for Service

The PLC automatics is equipped with extensive software for easy control, maintenance and testing (interactive schemes of tube connection, testing programs allowing testing of safety elements of the device, calibration settings, etc).

Client Service Arrangement

The user service and support are fully secured by the wide-world net of BMT Medical Technology s.r.o. contract partners. We have a wide net of branded service working places, connected to the HOT-LINE service, which secures the quick reaction on the customer inquiries and requests. For securing of the user comfort and for possibilities of the quick and high-quality service intervention, a special diagnostic programme was developed. This all grants the low operational costs and the long device lifetime.

Environmental Awareness

The device meets all and any current environmental requirements. It represents no burden for the work and life environment. A powerful suction pump with built-in device for feeding water saving saves approximately 15% of operation costs. The unique construction of the steam generator with automatic desalting arranges permanently high quality of steam.

High quality materials guaranteeing long service life of the device are used for its manufacture. Optionally, the device can be equipped with an element for additional cooling of waste water, allowing its temperature setting. The device does not produce any harmful waste. Environment – friendly methods are used for its manufacture in the workshop. All the main parts of the device as well as the packages are recyclable.

The device consists of 95% of steel, 4% of other materials, 1% of electro material and plastics. Environment-friendly liquidation to be performed after dismantling by an authorised person in compliance with EU regulations, corresponding with the WEEE directive (Waste Electric and Electronic Equipment).